Thanks to their very high mechanical, thermal, structural and chemical performance, advanced ceramics can be used in a wide range of industrial sectors

Medical

Ceramic’s perfect chemical inertness makes it a widely used material in the medical field, both for equipment and implantable devices.

Thanks to its outstanding technical characteristics in terms of performance, this material can be used to produce cutting-edge products.

Other characteristics are also highly valued, such as its low thermal expansion, its electrical insulation properties and its thermal insulation properties, etc.

Electronics

Ceramics are widely used because of their size, stability over time and low expansion in the event of major temperature variations. Ceramics have also long been used in the manufacture of most electronic components.

For the electronics sector, we have developed micro-machining processes that enable us to offer housings and component supports, as well as larger, more complex parts.

We also use metallisation techniques that enable us to ensure conductivity in very precise places while retaining the high insulating power of ceramics. For the most complex applications, we can make ceramic-ceramic and ceramic-metal assemblies.

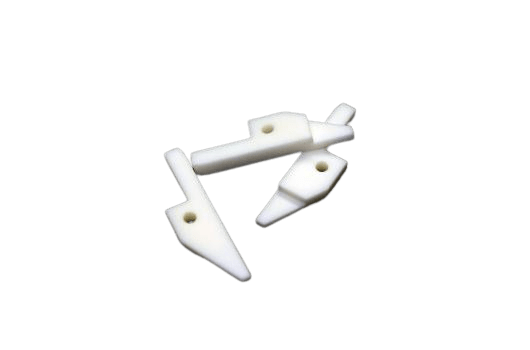

Aeronautics & Aerospace

Resistance to extreme temperatures with high amplitudes, electrical insulation, vibration resistance and corrosion resistance are the characteristics of the ceramics most appreciated in the aerospace sector.

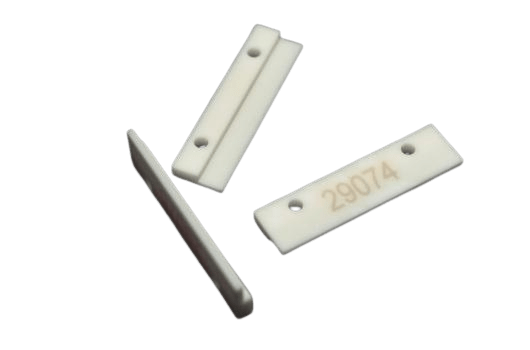

Equipment

Industry produces equipment for use in extreme conditions. For a very long time, ceramics have been meeting the most demanding requirements every time a part is called upon.

“When you’re not satisfied with other materials, there’s bound to be a technical ceramic that meets the need.

Cutting-edge sectors

The excellent properties of ceramics make them the materials to think about when standard materials reach their limits… They can be used to increase the technical characteristics of products or the productivity of processes.